high quality portable slurry pump factory

Latest articles

Slurry Pump

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreFlushing is defined as a fluid which is introduced into the seal cavity on the process fluid side, close to the seal face, and is normally used to cool and lubricate the seal face.

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreDredge Pump

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreThe Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreFrom an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreHow Slurry Pumps Differ From Standard Pumps?

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreSlurry Pump

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreThe size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreWhat is a slurry?

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read MoreTypes of slurry pump installation.

high quality portable slurry pump factory...

high quality portable slurry pump factory 【high quality portable slurry pump factory】

Read More

Popular articles

- >Slurry Pump VS Mud Pump

- WL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

- Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

- Consider the following.

- Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

- From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

Latest articles

Links

- Moreover, cast iron fence panels are relatively low maintenance

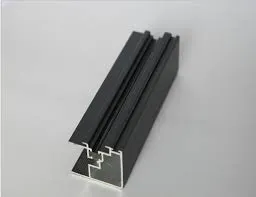

- Sliding screen doors have become an essential feature in modern homes, offering convenience, ventilation, and an unobstructed view while keeping insects at bay. A critical component of this functional design is the roller track, which ensures smooth operation and longevity. This article delves into the importance of the sliding screen door roller track and its role in maintaining the efficiency and functionality of the door.

Adjust the height as needed to ensure the door sits evenly on the track Adjust the height as needed to ensure the door sits evenly on the track

Adjust the height as needed to ensure the door sits evenly on the track Adjust the height as needed to ensure the door sits evenly on the track